Customer-centric. Through the management of R&D, manufacturing, quality and supply chain, we can take quick action to quality and cost control. In addition, we can meet customer needs and create value for them by reducing costs and improving efficiency.

Strict implementation of 6S management, effective management of production factors such as personnel, machinery, materials and methods.

CYGIA introduced ERP system for material control that makes each component to be traceable in the process.

Develop MES production information management system to achieve a reliable, comprehensive and feasible manufacturing synergistic factory management platform.

Implement a strict system of secrecy. All workshops ban all unauthorized mobile phones, computers and other equipment with the cameras. There are security and inspection to strictly control each channel.

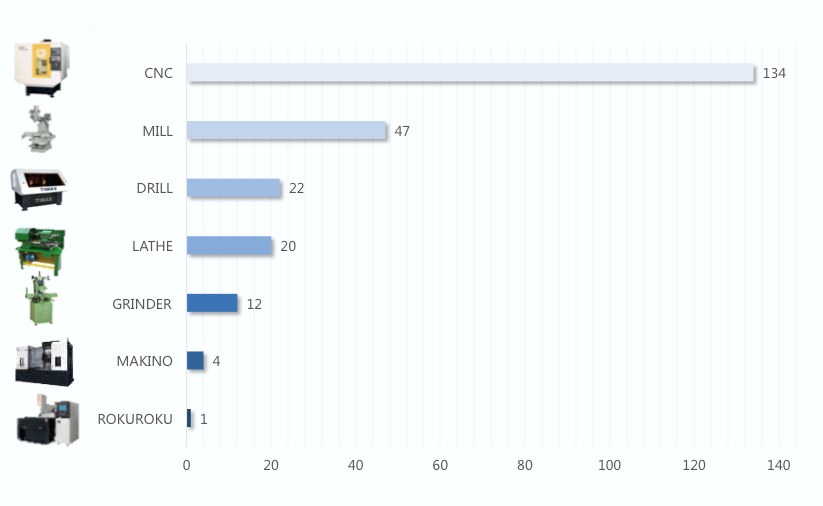

We have the first-class equipment production and processing capacity, the production workshop over 30,000 meters.

At the same time, we have the first-class machinery processing ability, various machinery processing equipment and the technical personnel.

CYGIA strictly implements ISO 9001 quality management system, insisting to satisfy customer demands and exceed customer expectations running through project kick-off, design, manufacturing, shipping and on site service.

CYGIA uses advanced measurement equipment, e.g., CMM, 2.5D projector, X-Ray Spectrograph, 3D Microscope, in the meantime, adhere to 6Sigma-DFSS/DMAIC/Lean, GR&R, CPK, QCC method to ensure raw material and process.