◆ Total 21 sets equipment, including pressing/ screwing/ induction welding/ dispensing/ curing/ cooling/ leakage test/ laser welding/ laser marking etc.

◆ Apply Pallet + Auto Conveyor + Cobot to achieve DUT assembly full automatically.

◆ Compatible to various products, only need to replace pallet and switch program.

◆ Potting combine to curing and cooling, save occupied space.

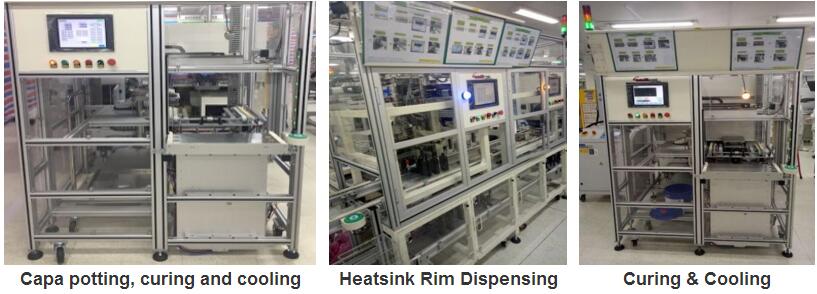

Different Dispensing and Curing Station

◆ Integrate ** Dispensing System to dispense on different parts by using different kinds of glue.

◆ Auto conveyor for Product transferring, scanner to check datamatrix for poka yoke.

◆ Camera to check dispensing effect.

◆ XYZ for flexible dispensing trajectory.

Cutting and Induction Welding Integrated Station

◆ Integrate Cutting and Induction Welding function.

◆ IA Fixture designed for Capacitor Cutting.

◆ Integrate CEIA induction welding system for the cut Capacitor induction Welding.

◆ Camera to check welding status.

◆ XYZ + Rotation for each welding head, flexible with various product.

Vertical and Horizontal Screwing Station

◆ Integrate ** Screwing System for Vertical and Horizontal Screwing on different stations:

Location guiding/Anti Return/Smart Stopper;

Torque accuracy : Max. Torque+/- 10%;

X/Y position: +/- 0.1 (Z/0.5);

◆ Auto Capa Block pick up and place.

◆ XYZ for each screw driver, flexible with various product.

Capa Potting and Plasma Treatment

◆ Lead ** Potting and ** Treatment.

◆ Auto label application, scanner to check datamatix for poka yoke.

◆ Camera to check potting effect.

◆ XYZ for flexible dispensing trajectory.

◆ Apply Oven to cure and cool the potted Capa Block.

◆ Pallet to carry 8 products go through whole station: Manual loading=>Auto move to potting position=> Scanner for poka yoke=>Auto move to curing conveyor=>Auto move to cooling conveyor=>come back to loading position.

◆ Camera to check potting effect.

◆ XYZ for flexible potting position.

◆ Potting combine to curing and cooling, save occupied space.

Sealing Testing Station

◆ Apply ATEQ D520 for debit test and F620 for leakage test.

◆ Manual turn table for cost saving, movable fixture for fast conversion.

◆ Manual turntable for leakage test and loading/unloading simultaneously.

◆ Scanner for poka yoke.

Multi-Functional Station

◆ Multi-Functional station for six functions:

1\ Manual Loading for PCBA & Housing; Sensor applied for Poka-yoke / Presence/ in Position.

2\ Calibration for Dispensing Needle, Scale for Dispensing quantity(CPK).

3\ XYZ module for PCBA pick up & place.

4&5\ Heat Stacking. Integrate Bd-tronic Heat Stacking System to control temperature and height.

6\ Camera inspection.

◆ movable fixture for fast conversion.